TECSEDO® BASE

Panels featured with traditional joint made to guarantee repeated opening/closing cycles and to enable good long-lasting

resistance to extreme weather conditions. Doors made of TECSEDO® BASE panels, together with accessory kits of the most

important worldwide suppliers, have been successfully tested according to EN 13241-1 standard, under the supervision and

approval of SP, Technical Research Institute of Sweden.

TECHNICAL SPECIFICATIONS

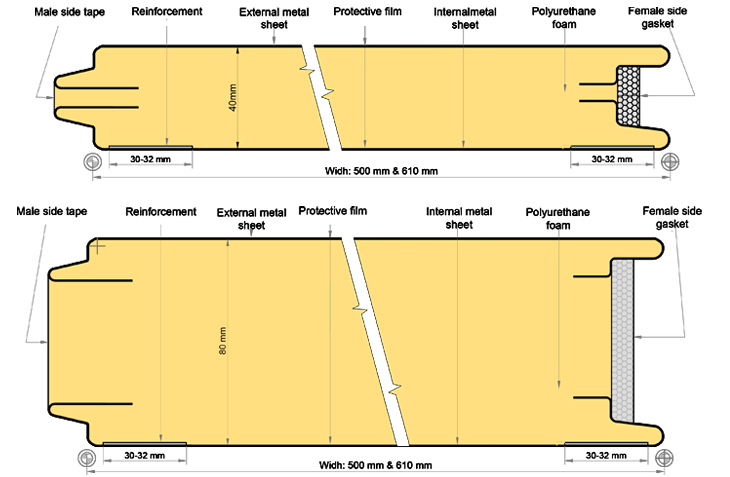

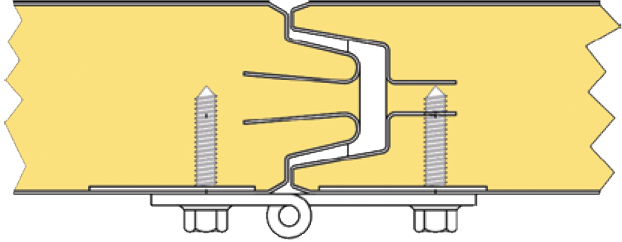

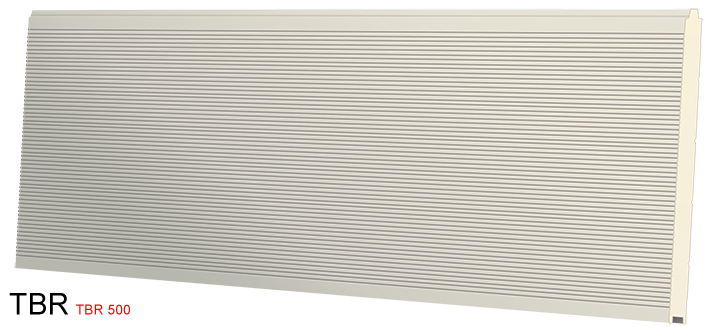

Panels available in 500 mm and 610 mm module External structure: prepainted galvanized steel, or aluminium, on both sides Coatings: 25 µm Polyester or Plastisol 200 ?µm (on request) Panels with traditional joint Panels thickness: 40 mm or 80 mm (nominal) A PVC sealing tape is applied during the production phase to the panel nose Insulation: high-density (40 kg/m3) self-extinguishing, HCFC-free, closed cells, polyurethane foam Female side is fitted with sealing foam gasket providing air and water tightness (both Class 3, according to EN 13241-1) Both sides are protected by adhesive polythene film (to be removed before installation) 2 longitudinal steel reinforcements are placed at hinge position to guarantee secure fixation.CONDITIONS

Standard length: 13,500 mm (Max.) – Standard packages contain 18 panels Packaging: panels are wrapped by extensive polythene and positioned on polystyrene slabs over analogue support blocks (polystyrene sheet can be applied on the upper panel on request).

Specifications

Fixing

Models

Dimensional standard

Certificates

| Thickness: | + 1-2 mm |

| Length: | ± 5 mm |

| Width: | ± 2 mm |

| Out Of Square: | < 0.5% of the total width |

| Bowing: | < 2 mm/m; max = 10mm |

| Height of microgrooves: | ± 1 mm |

| Skew of metal parameters: | 2 mm max |

| Flatness L=distance between the edges of measuring s = shifting aside The size of S to be taken every 1000 mm | L < 300 mm; s ? 1% 300 < L < 1000; s = 3 mm max |

| Metal sheets: | following EN 10147 and EN 10143 |

| Aesthetic requirements: | ECCS European convention recommendation of metal construction Part II “Good practise” |

| Prepainting systems: | ECCS European convention recommendation of metal construction Part I “Design” – point 2.5.3 |

| Brillance: | following EN 10169 |

Specifications

Fixing

Models

Dimensional standard

Certificates

|

CERTIFICATIONS FLEXIFORCE INDUSTRIAL CERTIFICATIONS TECSEDO |